Historically, the mining industry has been characterized due to its capital-intensive operations along with intricate logistical barriers and is undergoing a profound transformation now. At the heart of this transition happens to be the integration of advanced digital technologies, especially Digital Twins and artificial intelligence. These innovations are indeed reshaping how mining companies happen to approach their functional efficiency, sustainability, safety, and also decision-making, which is strategic.

As the industry looks forward to optimizing its processes in the middle of fluctuating commodity prices, as well as rising environmental concerns, the role that twins and AI play has emerged as a critical lever so as to unlock the new levels in terms of intelligence and flexibility.

Digital Twins and AI in mining – an overview

Digital Twins happen to be virtual replicas of physical assets, processes, and entire systems that are created by way of the integration of real-time sensor data, advanced modeling techniques, and IoT devices. These digital counterparts help with continuous simulation, evaluation, and optimization by way of mirroring the functional state of physical assets. Combined with AI, especially machine learning platforms, which evaluate massive datasets, Digital Twins go on to become incredibly powerful tools when it comes to predictive insights along with autonomous decision-making.

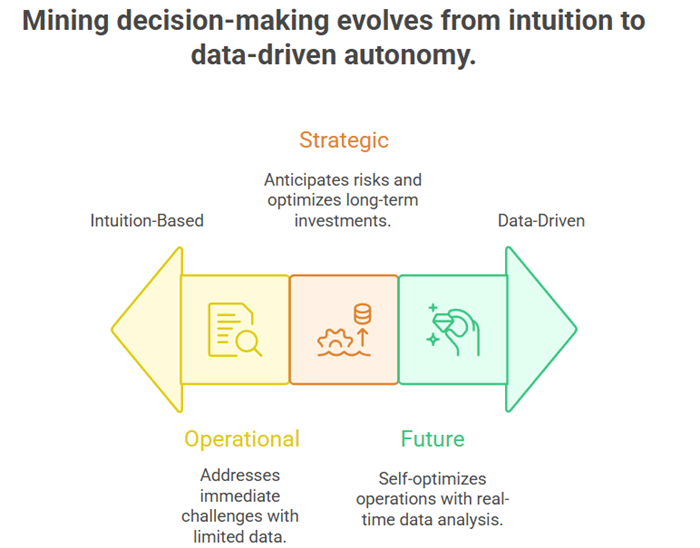

When we talk of the mining industry, in particular, Digital Twins simulate the mine operations, ore extraction processes, machinery performance, and environmental effects. AI elevates the simulation capability by way of learning from historical data, thereby anticipating potential failures and also recommending actions that are optimal. The synergy of Digital Twins along with AI goes on to create a very intelligent and dynamic ecosystem that elevates the decision-making process from intuition-based to driven by evidence.

The integration of Digital Twins and AI in mining operations goes on to represent a paradigm shift in how the sector approaches safety, efficiency, and sustainability. Environmental monitoring reaches new precision with IoT-enabled Digital Twins, which track air quality, water usage, and ground stability. AI cross-references this data along with geological surveys and weather patterns in order to forecast risks like sinkholes or contamination spread. In ore processing, machine learning optimizes the extraction yields by altering crushers’ settings and chemical dosages dynamically, thereby often improving the recovery rates. The true power lies in the fact that AI does not just recommend actions but autonomously executes them. Autonomous haul trucks reroute based on the real-time pit conditions, while smart grids balance energy usage throughout operations. Blockchain integration adds transparency to ESG reporting by way of immutably logging emissions or water recycling data. As 5G networks expand, edge computing will enable these Digital Twins to process data locally across remote mines, thereby helping near-instant decisions. This is not just digitization, but it’s the dawn of self-optimizing mines where every decision happens to be data validated and every risk is preempted.

-

Transforming the operational decision-making

Operational decision-making within mining is often constrained due to incomplete information, geological conditions that are unpredictable, and safety risks. Digital Twins, along with AI, collectively go on to address these challenges by way of offering real-time visibility along with predictive insights. For example, a digital twin of a mining operation can track equipment health by way of sensor data, pinpoint early signs of wear or malfunction, and also schedule the maintenance in a proactive way. The predictive maintenance prominently decreases the unplanned downtime, which historically goes on to account for substantial productivity losses.

It is well to be noted that, besides this, AI algorithms consistently evaluate operational data, optimize the resource allocation and haulage routes, and even process the schedules. This not just improves efficiency, but at the same time, it also elevates safety as the potential hazards, unstable ground conditions, or equipment failures get flagged well before they even occur. This kind of capacity to simulate numerous scenarios, right from energy consumption to environmental emissions, helps decision-makers to analyze the impact when it comes to different strategic choices in an instant way.

Another compiling example is how a large mining company using Digital Twins combined with AI simulates the entire extraction process and helps the operators to optimize blast designs, decrease any sort of waste, and also enhance recovery rates. Such kinds of intelligent decision-making frameworks are becoming the norm, thereby enabling the companies to remain competitive in a market that is volatile while at the same time complying with the strict environmental benchmarks.

-

Elevating the safety as well as sustainability

The significance of safety and environmental stewardship when it comes to mining cannot be overstated. Digital Twins and AI in mining prominently contribute to these priorities by way of fostering safe work conditions and also reducing ecological footprint. In underground mines, for instance, sensor data, which is integrated into Digital Twins, can track rock stability, gas levels, as well as ventilation systems, thereby providing an early warning system for potential collapse or even hazardous atmospheres.

AI models evaluate these data streams, thereby offering real-time alerts as well as recommendations for evacuation or risk mitigation strategies.

When it comes to the sustainability front, Digital Twins simulate the environmental effects like water usage, land disturbance, and emissions. By way of modeling varied operational scenarios, mining companies can pinpoint practices that optimize resource efficiency and also decrease environmental damage. This kind of proactive approach syncs along with the evolving regulatory benchmarks and societal anticipations in terms of greener mining practices.

Moreover, AI-driven, autonomous systems, like trucks, robotic assistance, and drills, function with Digital Twins, thereby decreasing exposure to dangerous environments and at the same time enhancing the overall safety performance. This kind of integration goes on to create a safer and more resilient mining ecosystem that happens to have the capacity of adapting in a swift way to the operational as well as environmental alterations.

-

Strategic planning along with long-term decision-making

While the operational efficiency is indeed crucial, the role of Digital Twins and AI in mining happens to extend to strategic planning and long-term decision-making as well. As mining companies chart their future when it comes to their assets, these technologies offer invaluable insights in terms of reserve estimation, the life planning of the mine, and also investment prioritization. Digital Twins help with detailed simulations of different mining scenarios that consider economic, technical, and environmental variables. AI algorithms evaluate these simulations in order to identify optimal investment strategies, forecastlong-term expenditures, and also analyze the risks that are associated with new exploration or expansion projects. This kind of data-driven approach decreases the uncertainty and, at the same time, elevates the confidence in strategic decisions.

Besides this, Digital Twins also help with continuous tracking of market conditions, commodity prices, and also geopolitical development by helping the companies to adapt their strategies in a dynamic way. The capacity to visualize the future scenarios and also evaluate their effects equips the leadership with the right tools in order to make informed decisions that are also resilient in a global market that is increasingly getting volatile.

The future of mining decision-making

Going forward, the convergence of Digital Twins and AI happens to promise to fundamentally reshape the decision-making processes within the mining sector by pushing the boundaries of operational intelligence. As sensor technology, the collection of data methods, and computational capacities continue to evolve, these tools are going to become increasingly predictive, autonomous, and also integrated into the elements of mining operations. This kind of trajectory will not just enhance efficiency as well as safety, but at the same time, it will also promote sustainability and resilience – elements which are very crucial in order to meet global economic as well as environmental demands.

It is well to be noted that one of the most compelling aspects of the future of mining decision-making happens to be the capacity to evaluate massive, multi-source data sets, and that too in real time. Advanced machine learning along with deep learning techniques will help the Digital Twins in order to process intricate geospatial, environmental, seismic, and operational data streams in a simultaneous way. This kind of integration enables hyper-accurate forecasts in terms of productivity, quality, equipment performance, and even effects on the environment. For instance, predictive models can as well forecast the exact timing when it comes to equipment failure months in advance by allowing the maintenance teams to plan interventions in a proactive way, thereby avoiding the costly downtime completely and even making sure that the unplanned outages are taken care of.

Besides this, the future will see the rollout of autonomous decision systems that function with minimal human intervention. These kinds of systems will leverage AI-driven insights in order to optimize drilling patterns, resource extraction, and blast designs in response to the fluctuating market prices or even the altering geological conditions. This level of automation can dramatically speed up the decision cycles, thereby helping mines to adapt rapidly to external variables like fluctuations in commodity prices or regulatory changes. Due to this, companies can maintain higher profitability margins and, at the same time, decrease operational risks.

Another transformative development happens to lie in the scenario simulation. Digital Twins, which are integrated with AI, will help the mining operators to virtually model future states of their assets as well as operations under varied conditions. The scenarios could very well include environmental constraints, workforce transitions, or even upgrades in infrastructure. By way of finalizing the outcomes of numerous strategies in a virtual environment, decision-makers can pinpoint the most sustainable as well as cost-effective and low-risk choice before committing valuable resources. This kind of approach elevates the strategic flexibility and, at the same time, helps in supporting long-term planning, specifically in global markets, which remain uncertain.

Furthermore, the evolution of blockchain technology along with secure data-sharing protocols will help unmatched levels of transparency and partnerships between diverse stakeholders. Regulators, local communities, investors, and environmental groups will have access to trustworthy data feeds, thereby making sure that the decision-making processes are not just data-driven but at the same time are transparent as well as accountable. This kind of transparency will foster greater stakeholder engagement and, at the same time, support socially responsible practices in mining.

What are the challenges and considerations?

In spite of the promising prospects, challenges still remain. Data quality along with integration happens to pose major hurdles, as mines often function with legacy systems as well as disparate data sources. Making sure of data security, especially in remote or politically sensitive regions, needs robust cybersecurity measures. Besides this, the high initial costs in digital twin infrastructure and AI technology can also be a barrier for certain smaller or even less mature companies.

There is also an ongoing requirement for skilled personnel who are capable of developing, managing, and also interpreting these intricate systems. Evolving regulations along with standards that are related to data privacy, environmental safety, and also functional transparency are going to influence how these technologies are getting rolled out and governed.

Conclusion

The role when it comes to Digital Twins as well as AI in enhancing decision-making within the mining sector is all set to expand quite significantly in the years to come. These technologies empower mining companies in order to operate in a more efficient, safe, and sustainable way by way of offering real-time insights, predictive evaluations, and scenario simulation capacities. As the industry continues to take into account digital transformation, the convergence of Digital Twins and AI is going to become a landmark when it comes to strategic planning, functional excellence, and stewardship in the environment.

It is well to be noted that the future of mining happens to lie in harnessing the entire potential of these innovations, creating a much smarter and more resilient as well as much more responsible resource extraction, which can go on to meet the global demands while at the same time safeguarding the planet. Industry leaders who happen to invest early within these digital ecosystems are going to position themselves right in the forefront of profitable and sustainable mining operations by shaping the evolution of the industry into the decade to come.