Mining company BHP has commenced autonomous drilling at its Spence copper operation in northern Chile. The firm has deployed the Pit Viper 351 model, which is operated remotely from the Spence Control Room located approximately 2km from the mine pit.

BHP expects the autonomous operation to reduce exposure to operational health and safety hazards for employees. The miner plans to deploy five autonomous drills at the Spence operations as part of its plan to make 100% of its drill pool autonomous.

BHP Minerals Americas autonomy head Pedro Hidalgo said: “The first autonomous drill in Spence is the spearhead of a broader programme that we are implementing in BHP’s main operations in Chile. We are not just working on drills, but also on autonomous trucks.

“We’re very happy to complete this first milestone, which will allow us to make further progress in the Autonomy Programme at both Spence as well as Escondida.”

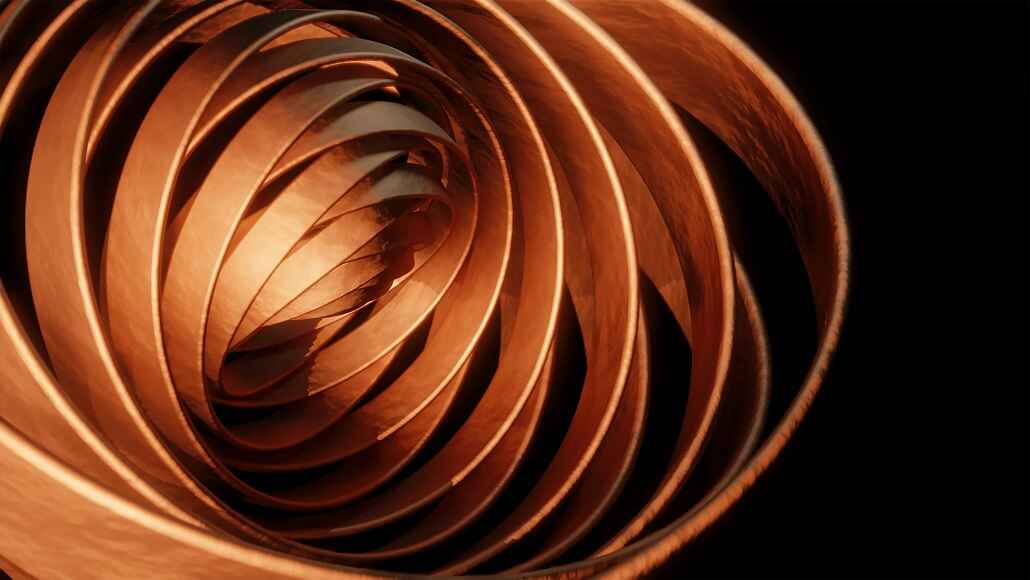

Last year, BHP completed the expansion of the Spence copper mine, with the construction of a $2.46bn concentrator plant. The facility is capable of processing 95,000 tonnes of raw material a day, reported Reuters.

The expansion project was intended to extend the operational life of the Spence open-cut copper mine by more than 50 years. In August 2021, BHP teamed up with construction and mining equipment manufacturer Caterpillar to develop and deploy zero-emission trucks as part of a plan to reduce emissions at mining sites.

The partners also evaluated options to implement the new technology at BHP-owned mining sites to reduce operational greenhouse gas emissions.