Swiss engineering firm ABB has secured a $103m contract from Brazilian mining giant Vale to supply and install electrical and automation systems at its $17.6bn Carajas Serra Sul iron ore project (S11D) in Para state, Brazil.

This latest contract follows the $140m deal signed by the firms in September 2012 for the first phase of the S11D project, where ABB was required to install the primary transmission substation that allowed Vale to operate the process plant.

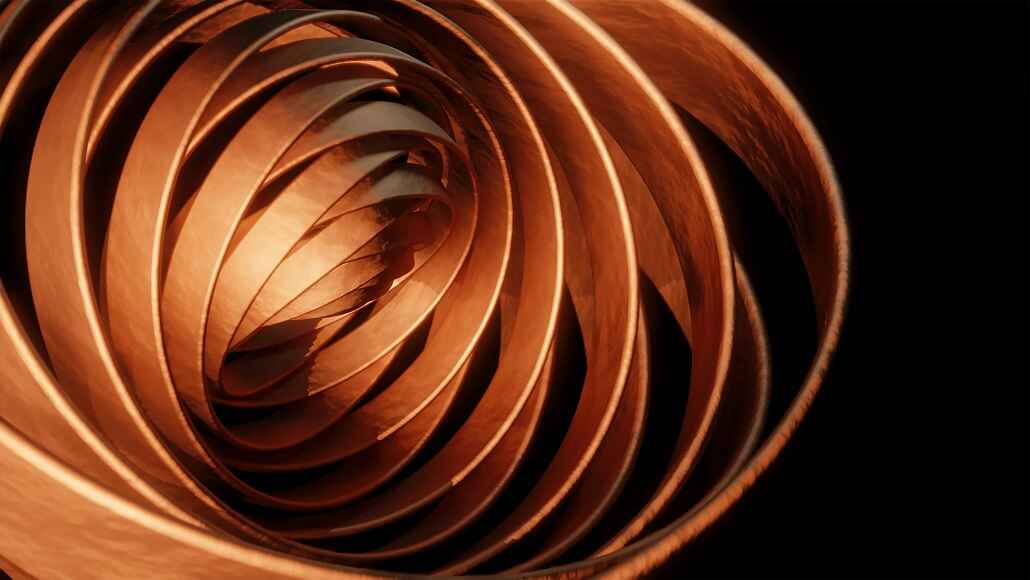

For the new order, ABB will supply a 230KV in-feed substation and 42 secondary substations to Vale in order to expand the mine’s capacity.

The in-feed substation will connect the site to the electricity grid to provide power for all mining operations. The secondary substations will be deployed at ABB’s e-houses, prefabricated, walk-in, modular and outdoor enclosures to store electrical and automation equipment.

In addition to substations, ABB will also supply the motors required to drive the mine’s conveyor belts and electrification systems for excavators, stackers and reclaimers.

The company said in a statement: “If the S11D mine were to be operated using conventional means, it would need around 100 off-highway trucks that consume 77% more diesel per year.

“Truckless transportation will use conveyor belts to move rock and ore around the site with lower carbon emissions, reduced operating costs and greater safety than the truck-based system it is replacing. This is the first time such a solution will have been used on a large scale at an iron ore mine.”

The S11D Carajas mine is expected to produce 90 million tonnes of iron ore a year at its peak production capacity.

ABB process automation division head Veli-Matti Reinikkala said: “Cross-divisional collaboration on this project is enabling tight power and automation integration, a key differentiator for ABB.”